-

-

Call for inquiry

-

Port Trade Center, SMCHS

Karachi, Pakistan

Sludge Dewatering

The residual water with high pollution loads is called sludge. We remove solid from liquid so that they can be separately disposed. The system which extracts liquid from sludge and thickens the waste is called sludge dewatering system. Abamet Pakistan offers a wide range of sludge dewatering systems for our clients and there is no ‘one size fits all’ technology for end users; rather, it becomes a choice based upon waste stream, size of facility, budget, staff, and other factors. Abamet Pakistan gives you designs for a suitable system according to your pollution load. We can see if this sludge can be a raw matter for some other industry too.

Screw Press

A screw press requires little operator attention and low maintenance, but consumes considerable floor space due to small hydraulic load capacity. In a screw press, a screw with a variable pitch helix operates within a cylinder of fixed and moving rings that make up the dewatering drum. The fixed rings form a static structure whereas the moving rings ensure continuous self-cleaning while the screw is in motion. When the screw is in operation, the size of the gaps changes continuously, thus giving a smooth dewatering process. The filtrate that results from the dewatering process as the flocculated sludge is compressed, flows through these gaps into a collection tray located under the machine.

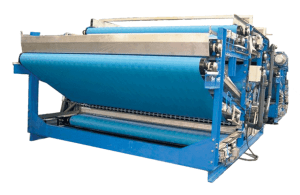

Belt Press

Belt filter larger output, low consumption, smaller working space, better working condition, easy-operation and convenient maintenance. Sludge goes into sludge distributor to gravity dehydration which is a little long period with horizontal movement and small angle rising period; then filtrated sludge moves with filtrating belt and under gravity water is separated from solids. This immobilized sludge is taken to wedge dehydration. Where two filtrating belts come together and squeeze sludge gradually discharging the water. After discharging device, mud cakes are scraped by scraper from filtrating belt.

Centrifugal Decanter

Spiral precipitated centrifugal is a high efficiency equipment for discharging and separation and precipitation. With a certain differential, drum and spiral rotate equidirectionally in a high speed. The material is introduced into the spiral internal cylinder through feed tube, then enters nto the drum in a faster speed. Under the effect of centrifugal field, the heavy solids form a sediment layer on the drum wall. The spiral will transport the solid phase content to the cone part on drum and it will be discharged through the bleed hole. This machine can continuously feed in, separate, wash and discharge in the full speed of running.

Filter Press

A filter comprises a set of vertical plates, which press against each other by hydraulic jacks at one end of the set. The pressure applied to the joint face of each filtering plate must withstand the chamber internal pressure developed by the sludge pumping system. This vertical plate layout forms watertight filtration chambers allowing easy mechanization for the discharge of cakes. Filter clothes finely or tightly meshed are applied to the two grooved surfaces in these plates. Solids sludge gradually accumulates in the filtration chamber until the final compacted cake is formed. The filtrate is collected at the back of the filtration support and carried away by internal ducts.